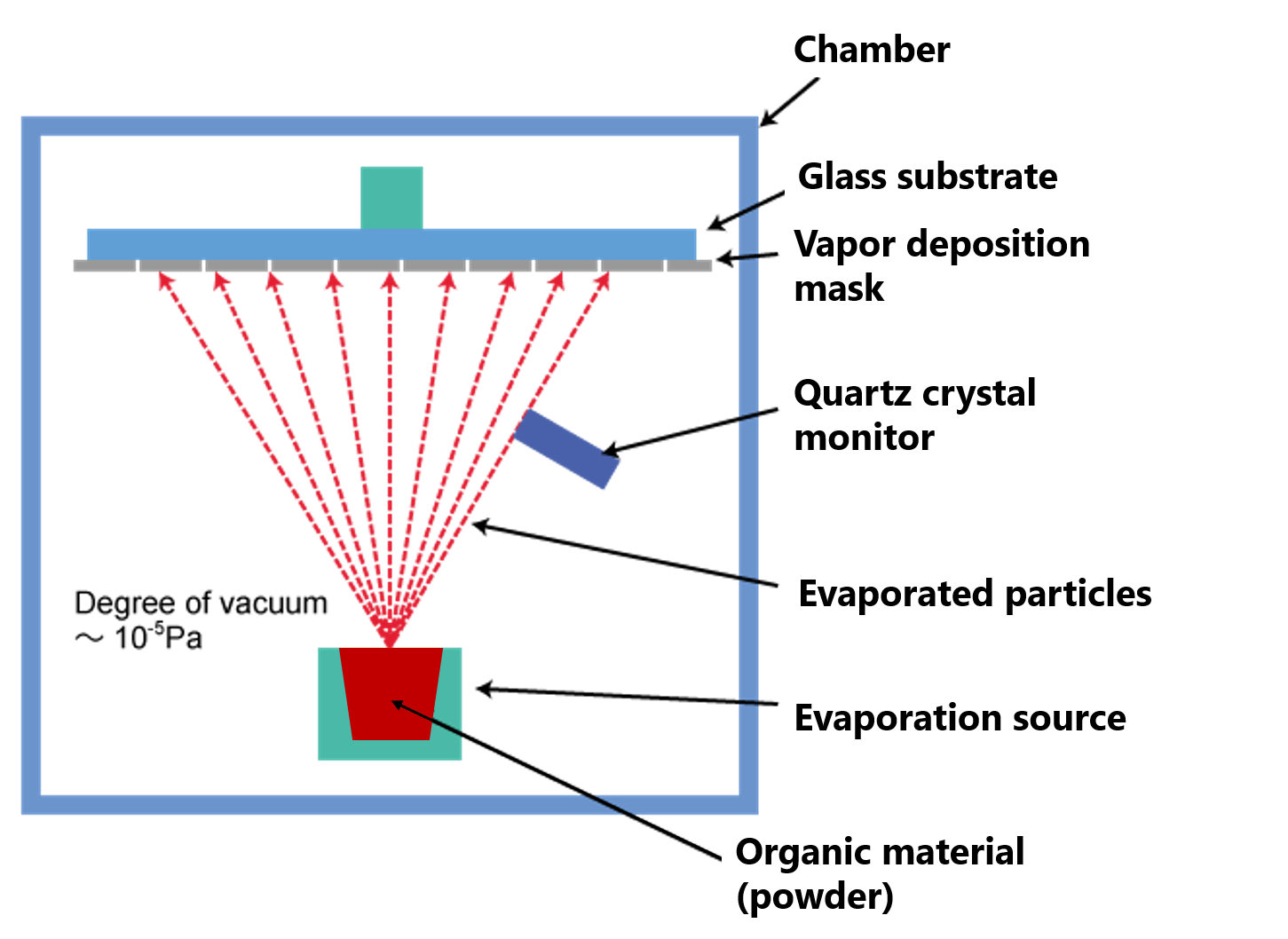

Inside the chamber is kept to a high vacuum condition of about 10-5 Pa, and organic material is poured into the evaporation source and heated to about 300 degrees Celsius until it evaporates. The evaporated particles ejected from the evaporation source maintains their linearity and adhere to the glass substrate without colliding with other particles. The speed of evaporated particles (deposition rate) is measured with a quartz crystal monitor and controlled to make sure it is constant, and the deposition is finished when the coating reaches a prescribed thickness.

To obtain the RGB emission color, the host material is doped (added) with a slight amount of dye material of about several percent. In this step, two types of organic materials are deposited simultaneously to form a mixed deposition. This is called codeposition.

And in the final step, metal electrode film is formed. Silver and aluminum are used in this step, and the evaporation temperature is as high as 1,000 degrees Celsius or more, unlike with organic material.

The OLED's deposition process is characterized by the procedure of performing deposition and RGB patterning at the same time.

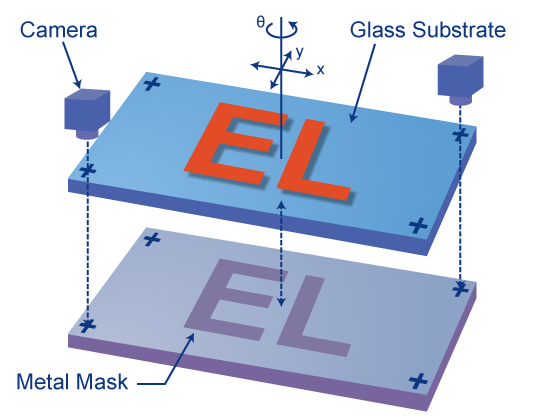

With organic material, patterns cannot be etched after the deposition is completed. Therefore, deposition masks are used during deposition in the patterning process. This step requires using the alignment technology for aligning the deposition masks with glass substrates with high precision. Alignment is performed by using a cameras to capture the deposition mask and glass substrate positions and then precisely controlling the positional relationship between these two.

In recent years, smartphones and TVs are using higher definitions for their screens. We are using our alignment technology to support the evolution of image quality to 4K and 8K.