This page describes the mass production process that uses the vacuum deposition method, which is currently the mainstream method.

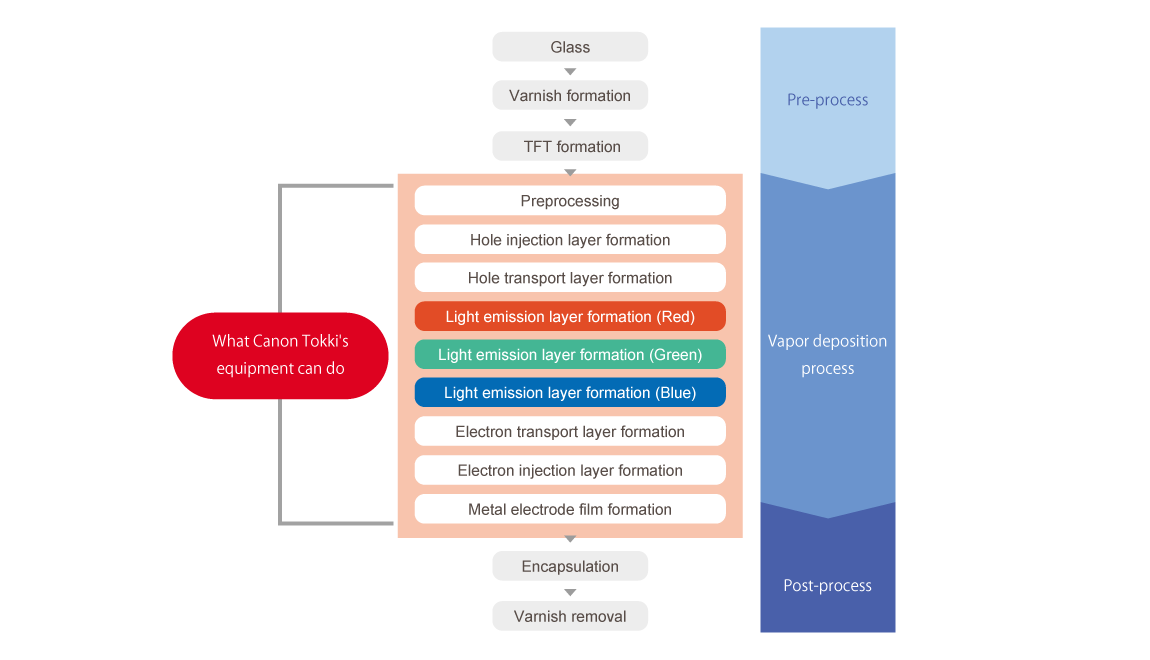

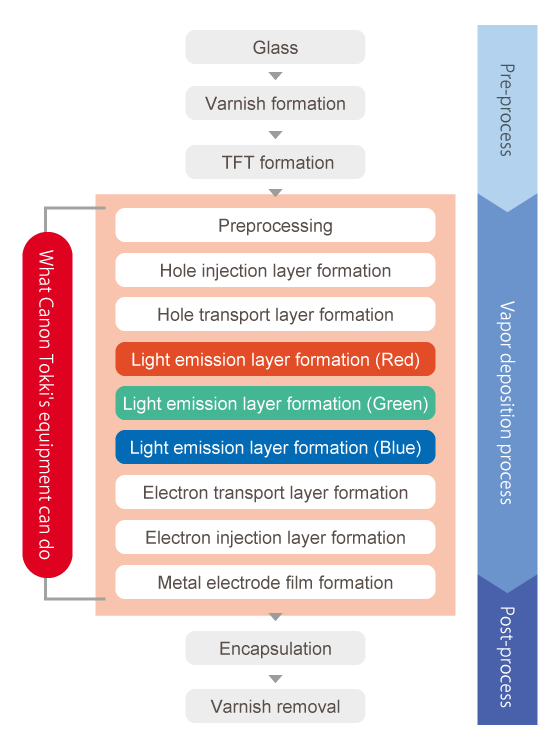

The above figure is an example of the process of manufacturing a flexible OLED panel, using the vacuum deposition method.

The mass production process is divided into three steps: "pre-process" that primarily makes TFT circuits, "vapor deposition process" that mainly deposits organic material, and "post-process" that consists of sealing, cutting, and wiring connections.

Emission layers are adhered on to glass substrates in the vapor deposition process, but various techniques are required to produce high definition and high-quality panels. The main required techniques are (1) technique of producing a vacuum vessel with a clean and high vacuum environment inside, (2) FA (factory automation) technology for moving glass substrates at high speed and precision, and (3) deposition and alignment technologies with high precision controlling of the position where emission layers are coated on glass substrates. For all of these techniques, we have the technical expertise accumulated over the years through development of various devices. And we also have abundant experience in successfully providing equipment for mass-producing display panels.